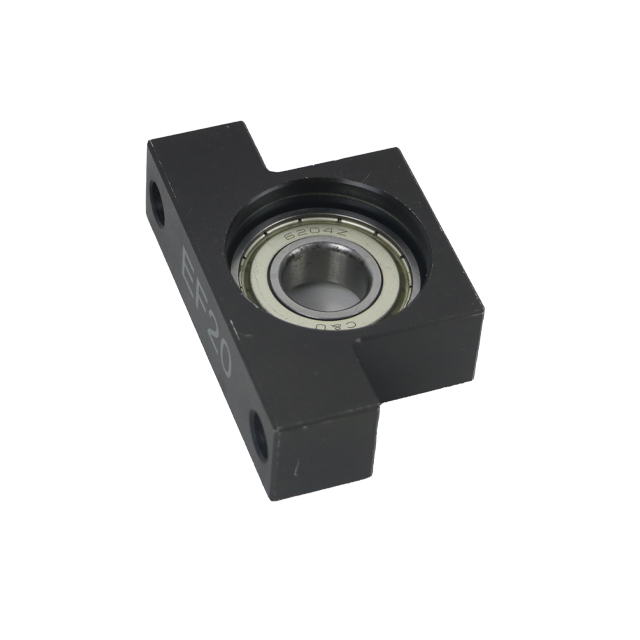

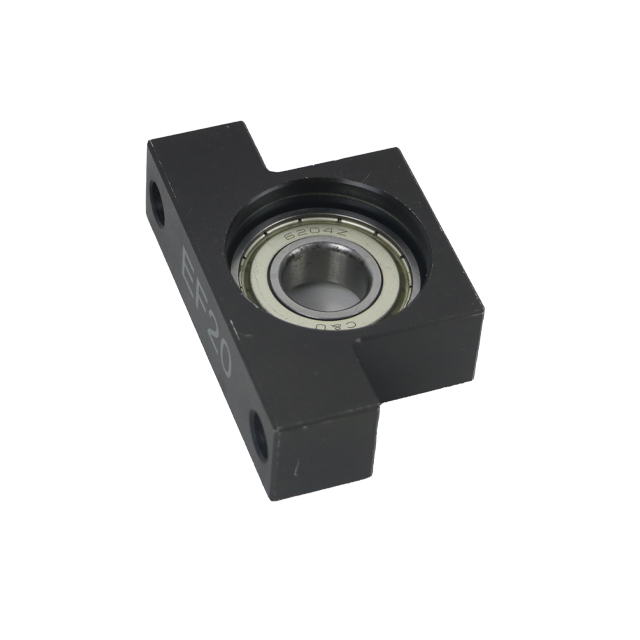

Ⅰ.Characteristics of the EF20 Support Block

1.Structural Design

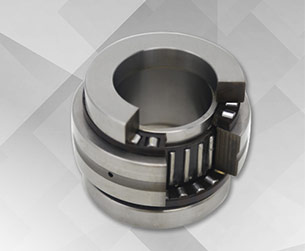

Built-in Angular Contact Bearings: Typically equipped with JIS Class 5 angular contact bearings that have undergone preload adjustment. These bearings can withstand both radial and axial loads simultaneously. Moreover, the preload treatment effectively eliminates internal clearance within the bearings, enhances the rigidity and rotational accuracy of the system, ensures smooth operation of the lead screw, and reduces vibration and noise.

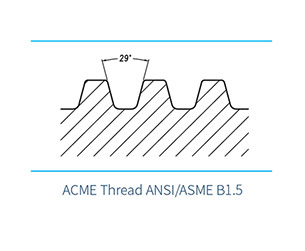

Strong Adaptability: Designed specifically for the end shape of finished precision ball screws of the BNK type. It has a high degree of compatibility with lead screws of the same series, and after installation, it ensures precise connection and stable operation between the lead screw and the support block.

2.Performance

High Precision: Benefiting from the high precision of the angular contact bearings and its own precision manufacturing process, the EF20 support block can provide high positioning accuracy and repeat positioning accuracy for the lead screw. It is suitable for occasions with extremely high requirements for motion precision, such as precision machining machine tools and optical equipment, and can ensure the accuracy of equipment processing or operation.

High Rigidity: The excellent structural design and high-quality materials endow the EF20 support block with high rigidity. This allows it to maintain a stable shape and position even when bearing large axial and radial loads, reducing deformation and thereby maintaining the stability and reliability of the lead screw transmission system.

Good Load-Bearing Capacity: It can withstand a certain range of axial and radial loads, meeting the load-bearing requirements for lead screw support blocks in general industrial applications. It can be applied to mechanical equipment that needs to drive relatively heavy loads, such as industrial robots and automated production lines.

Ⅱ.Load-Bearing Capacity and Application Scenarios of EF20

1.Load-Bearing Capacity

The basic dynamic radial load rating (Cr) of EF20 is approximately 8000N, the basic static radial load rating (Cor) can reach 15000N, and the basic static axial load rating (Cao) is about 7000N.

2.Application Scenarios

CNC Machine Tools: EF20 can provide high-precision support to ensure the accuracy and stability of lead screw transmission, thus guaranteeing the machining precision of the machine. It is applicable to CNC lathes, milling machines, grinding machines, etc.

Industrial Robots: Industrial robots require precise transmission and positioning during movement. The high rigidity and load-bearing capacity of EF20 support block can meet the requirements for lead screw support, and it can be used in joint transmission, arm linear motion and other parts of robots.

Automated Production Lines: On automated production lines, various mechanical components need to work in coordination. EF20 can be used to support lead screws, ensuring efficient and stable operation of the production line, such as in the mechanical transmission systems of material conveying and assembly links.

Ⅲ.Advantages and Disadvantages of the EF20 Support Block

Advantages

High Precision: The EF20 support block is usually equipped with JIS Class 5 angular contact bearings. Through precision machining and preload treatment, it can provide extremely high positioning accuracy and repeat positioning accuracy. It is suitable for occasions with strict requirements on motion precision, such as precision machining machine tools and optical equipment.

High Load-Bearing Capacity: Its basic dynamic radial load rating (Cr) is approximately 8000N, the basic static radial load rating (Cor) can reach 15000N, and the basic static axial load rating (Cao) is about 7000N. It can withstand large axial and radial loads, making it applicable to mechanical equipment that needs to drive relatively heavy loads, such as industrial robots and automated production lines.

Long Service Life: The internal bearings contain an appropriate amount of lithium soap-based grease and are sealed with special gaskets, which can effectively prevent dust and impurities from entering, reduce bearing wear, extend the service life, and lower maintenance costs.

Easy Installation: The EF20 support block features a reasonable structural design, and the preset threaded holes simplify the installation process. In addition, the bearings are pre-filled with appropriate grease and adjusted to an optimal state, requiring no additional adjustment or processing, and can be directly assembled onto equipment, reducing assembly time.

Compact Design: With a compact structure and high integration, the EF20 support block, while being larger in overall size than some small-sized support blocks (to meet load and precision requirements), can still effectively save installation space and is suitable for various mechanical structures.

Relatively High Cost: Due to the adoption of high-precision bearings, high-quality materials, and precision manufacturing processes, the production cost of the EF20 support block is relatively high, resulting in a higher market price compared to some general-precision support blocks. This may increase the overall procurement cost of equipment.

Strict Requirements on Installation Environment: To ensure the EF20 support block exerts its optimal performance, strict control over installation precision and environmental conditions (such as the flatness and perpendicularity of the mounting surface) is required during installation. Improper installation may affect its precision and load-bearing capacity, and even lead to equipment failures.

English

English